PREMIUM COMMERCIAL VEHICLES DISC BRAKE PADS

- Maximum Continuous Working Temperature 500 ํc

- Original Equipment Quality and Performance.

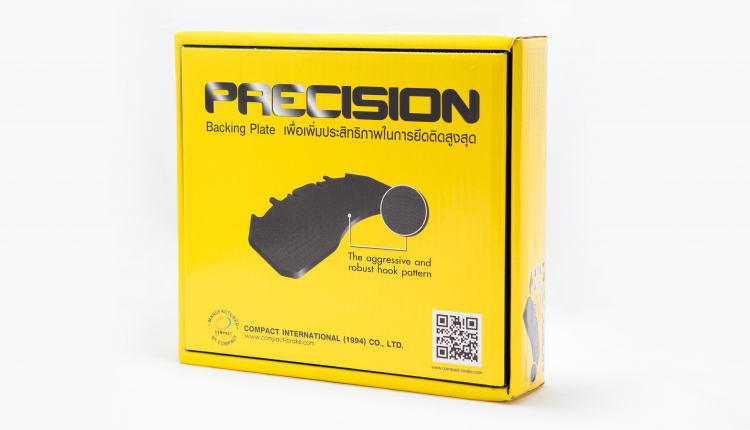

- Nano Technology disc brake pads for Commercial Vehicles.

- Use international Standrad for dynamometer test procedure.

- ISO 9001 and TS 16949 Standards.